Fiber cement board fixing system

As a typical riveting system, the main advantages of rivets are:

– quick and easy installation.

– it is possible to remove the cladding plates for any reason (installation of video surveillance, air conditioning, facade lighting) simply to drill the rivets, to dismantle the boards and then to re-install with new rivets.

– Vibration resistant system, ensuring long life of your facades.

– free thermal expansion and contraction of the plates (panels).

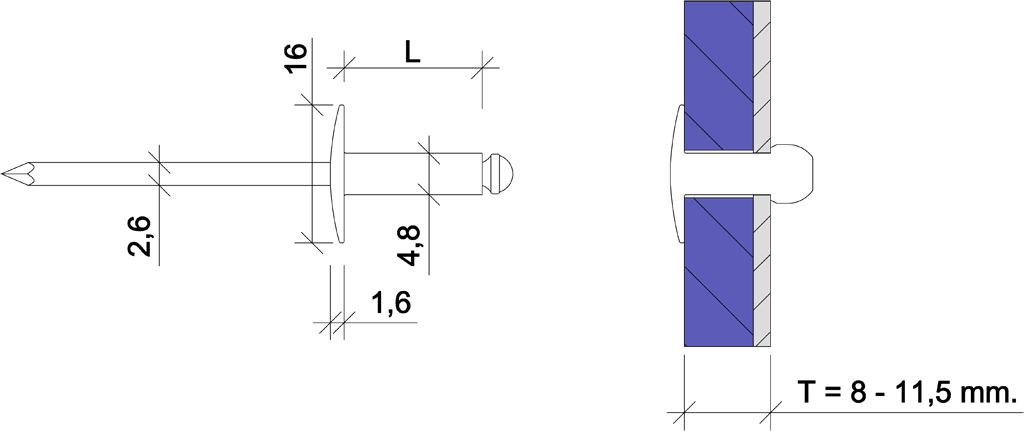

Specially designed blind rivets are used in this system. To ensure long and trouble-free use, the mandrel and rivet body are made of materials with high corrosion resistance.

The rivet shape is designed to look best with a very thin head (less than 1.6 mm).

A two-component, scratch-resistant coating is applied in each RAL color to match the cladding panels.

Rivet specifications:

Rivet strength:

Shear strength: 2107 N ± 10%.

Tensile strength: 2842 N ± 10%.

Materials:

Housing: Aluminum AlMg3,5

Donnik: stainless steel A2

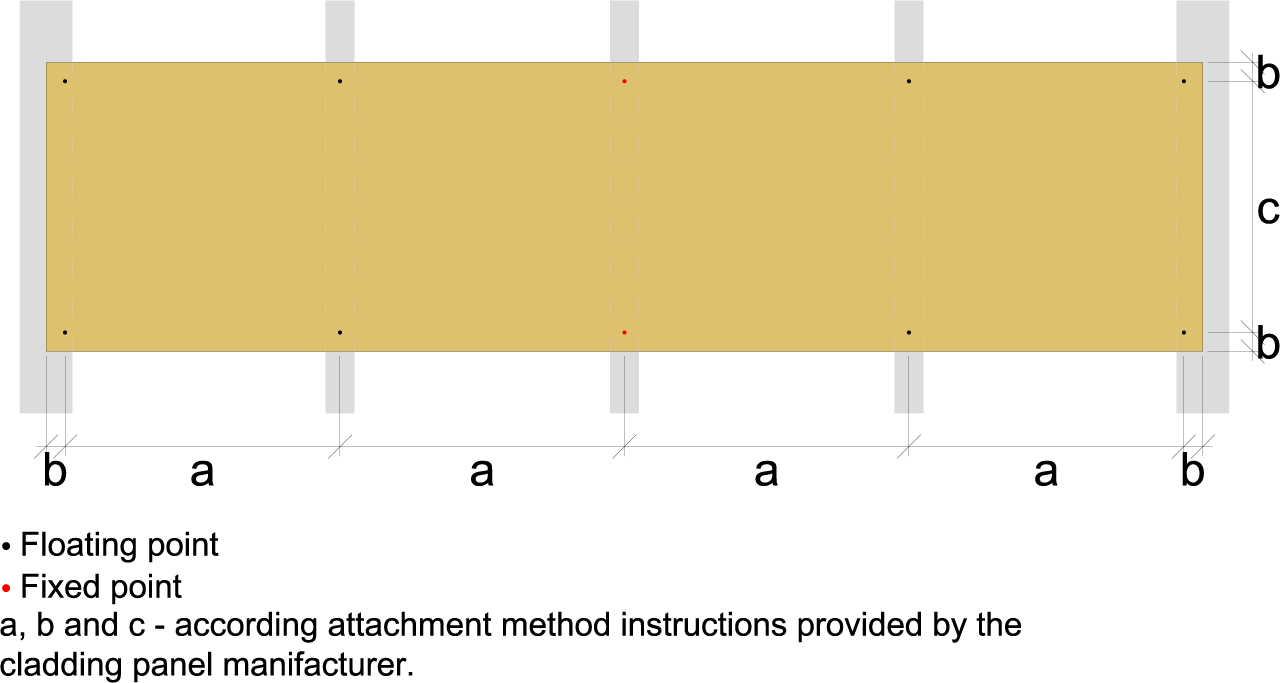

To ensure free thermal expansion and contraction of the slabs, there is a typical drilling method.

To ensure free thermal expansion and contraction of the plates, there is a typical method of drilling and fixing with aluminum sleeves.

The difference in this system is the use of special aluminum sleeves for fixed points.

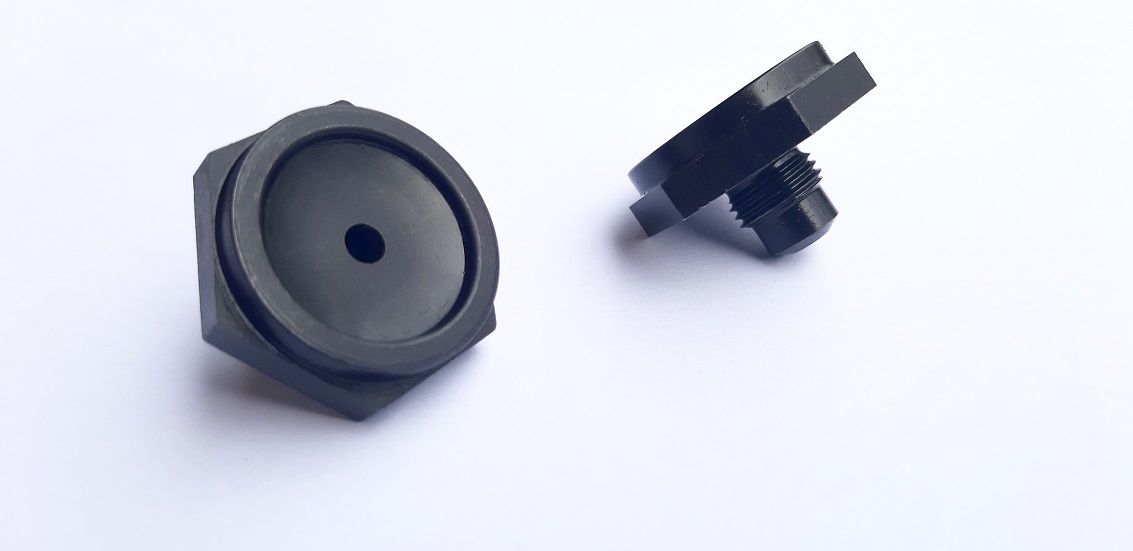

Sleeve specifications:

Each hole in the boards is made with a diameter of 9.5 mm. (standard, other diameters available on request).

The sleeves are used only for fixed points.

This system is very flexible and quick to install.

Additional accessories:

Special nose element for standard riveting tools.